Bean to Bar

Bean-to-bar refers to the process of making chocolate from scratch, straight from cacao beans. While there are many brands of chocolate on the market, only a handful make their own chocolate from the bean. The vast majority purchase pre-made chocolate called couverture which is then melted down and poured into molds.

Making chocolate from the bean is a time and labour intensive process, but it allows chocolate makers to fully control each step of the process and bring out the unique flavours of specialty beans from different regions. It also shortens the supply chain, often enabling chocolate makers to develop relationships directly with the farmers who grow, harvest, and ferment their beans. Below is a short outline of the steps involved:

Sourcing:

Cacao beans are the seeds of the fruit of the cacao tree. Much like terroir affects a wine’s flavour, there are many factors that can affect the flavour of cacao beans, from genetics, to soil, to climate, to post-harvest practices, particularly fermentation. Even beans from the same region of a country can produce chocolate with vastly different tastes. Beyond looking for unique flavours, we also value the importance of fair wages for growers and sustainable farming methods when sourcing our beans.

Sorting:

Prior to roasting, we sort our beans by hand to remove any that are broken, flat, or of poor quality.

Roasting:

The length and temperature of the roast is a major factor in the flavour of the finished chocolate. Different bean types may require different roasts to bring out desired flavors and remove undesirable ones. We use a coffee roaster as it allows us to precisely control our roasting profiles

Cracking:

After the beans are roasted, they are broken up into small pieces so that the shells can be separated from the nibs.

Winnowing:

If the outer shells (husks) of cacao beans aren’t removed, they can impart off-flavours to chocolate. In the early days of our chocolate adventure, we winnowed our cracked beans manually, using a rotating bowl and a hair dryer to blow the lighter shells away from the nibs. After months of getting lots of cacao shells all over the place, including into our hair, Dom and his dad built a winnowing machine which vastly sped up the process.

Refining/Conching:

Once the shells have been winnowed away, the remaining nibs are pureed into a paste and then tossed into one of our melangers. These machines contain two heavy granite wheels spinning overtop a stone slab which grinds the particles of the liquid cacao mass into a very fine consistency, giving the chocolate a smooth, creamy mouthfeel. This process also removes some bitter and acidic compounds, which mellows out the harshness of the initial cacao paste. We conch our chocolate continuously, often for at least 72 hours, depending on how we want the finished product to taste.

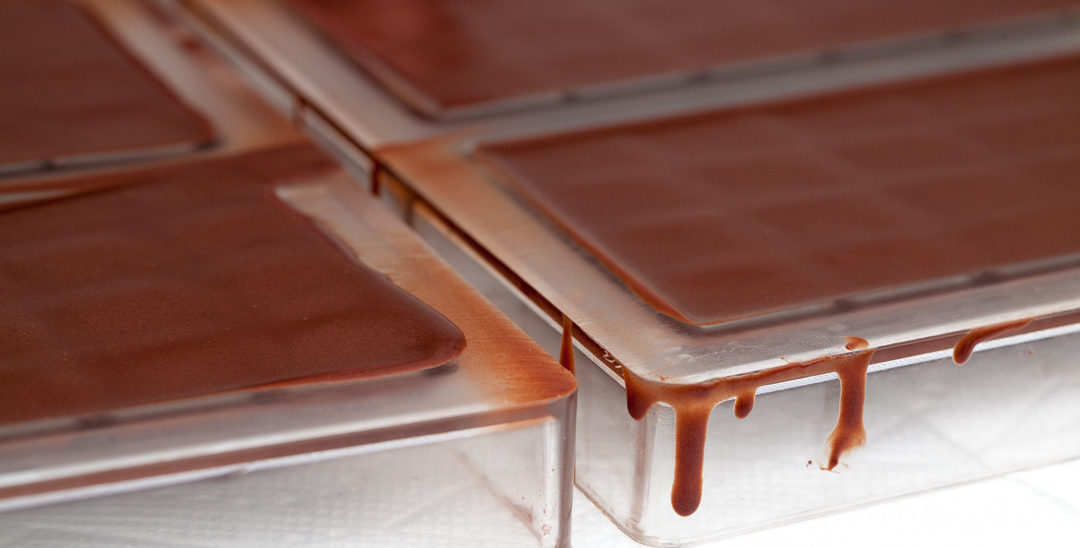

Tempering and Molding:

After the chocolate has been conched, it is allowed to cool in large blocks and sometimes aged for a time to allow flavours to develop. These blocks of chocolate are untempered; they look rough and have whitish cacao butter bloom on the surface. Tempering is a process of heating and cooling the chocolate in a specific way to achieve the correct crystal structure which gives it a smooth sheen and crisp snap when broken. The tempered chocolate is poured into molds, which go onto a ‘shaker table’ then into our cooler, and voila, we finally have finished chocolate – from bean to bar!